About 80% of CO₂ in the product life cycle is emitted at the time when a machine is in use at customer's factory.

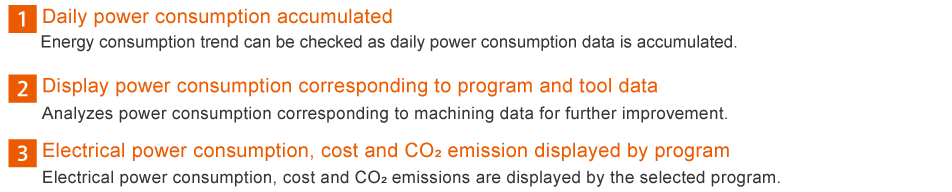

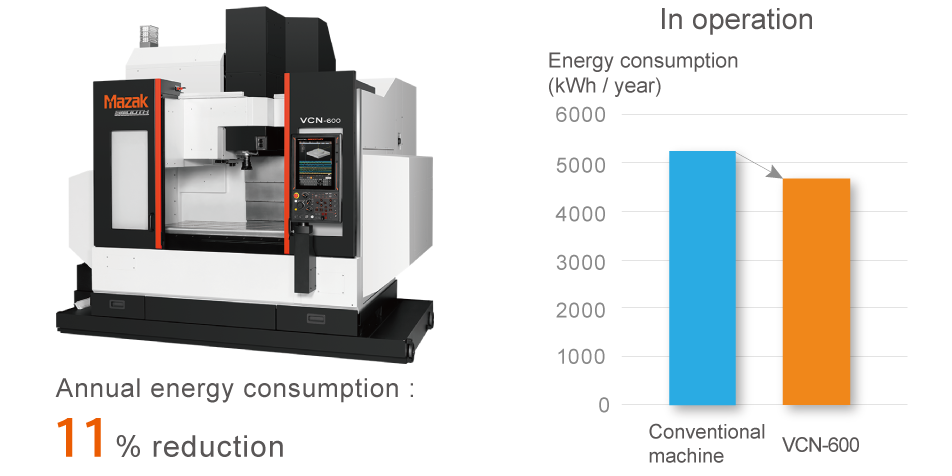

We will contribute to reducing the environmental impact at our customers' factories by developing new models and new functions with the consideration of saving energy.

High energy-saving chiller unit

Improved refrigerant inverter optimizes cooling capacity according to the spindle load during machining, achieving a higher energy saving rate.

Significantly reduced CO₂ emissions during machining

Hydraulic unit utilizing accumulator as well as an inverter type chiller unit resulting in considerable reduction of energy consumption in operation.

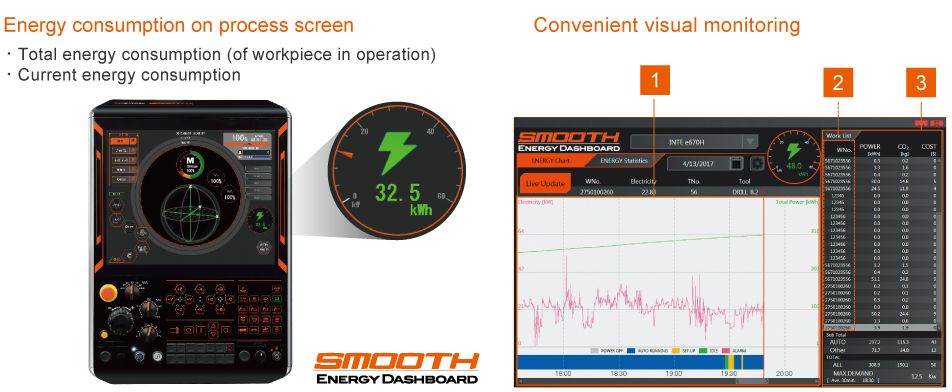

Smooth Energy Dashboard to manage the power consumption of machine tools

The Smooth Energy Dashboard provides the convenient visual monitoring of energy consumption. Electrical power consumption in real time and the history can be displayed. By analyzing the data corresponding to programs and tool data, this software can suggest improvements for electrical power consumption, management and reduction.