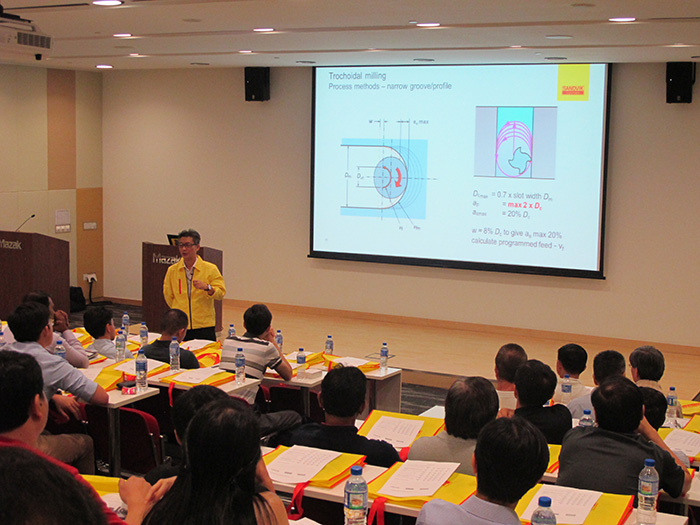

Mazak, Sandvik Coromant and OPEN MIND Technologies held a joint event on 3rd March 2016 to promote latest CNC machine tools, milling strategies and CAD/CAM solutions for achieving high efficiency in metal cutting. The focus of the event was to bring new & innovative milling strategies and achieving optimum machining efficiency for the precision metal cutting industry.

Sandvik Coromant unveiled their new CoroMill®390 insert endmill, which is designed for steel machining. It features diameter as small as 9.7mm and the design of the tool also allows easy accessibility while maintaining the strength and precision of the tool.

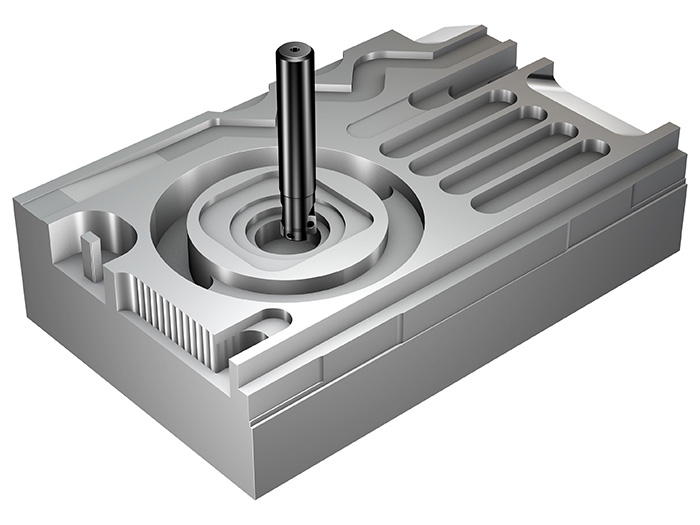

Mazak, Sandvik Coromant and OPEN MIND Technologies featured the live cutting of a jet engine bracket on Mazak latest 5 axis machine; VARIAXIS i500 using Sandvik Coromant's new CoroMill® high performance insert end mill, complemented by OPEN MIND Technologies trendsetting 5 axis technology in hyperMILL® which can typically yield up to 25% of time saving while lowering tool wear and increased contour accuracy for more cost- efficient production due to continuous machining.

Mazak, Sandvik Coromant and OPEN MIND Technologies featured the live cutting of a jet engine bracket on Mazak latest 5 axis machine; VARIAXIS i500 using Sandvik Coromant's new CoroMill® high performance insert end mill, complemented by OPEN MIND Technologies trendsetting 5 axis technology in hyperMILL® which can typically yield up to 25% of time saving while lowering tool wear and increased contour accuracy for more cost- efficient production due to continuous machining.

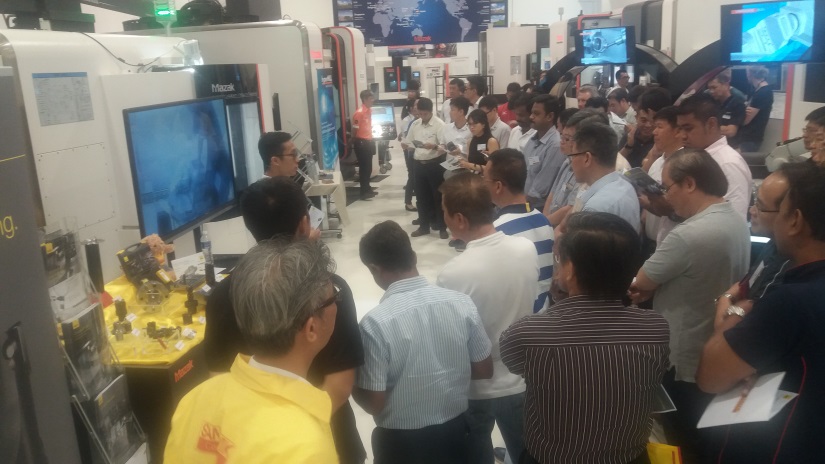

Mr Jerry Goh;Sales Engineer (Bottom Left) and Mr Chan Kok Fu (Bottom Right), Chief Consultant of OPEN MIND Technologies Asia Pte Ltd highlighting the benefits and capabilities of the hyperMILL®CAM software before the live demonstration.